Channel drainage

The meaning of terms

Included in ACO’s extensive surface water management array of products is the world’s leading range of channel drainage solutions. They are typically designed for efficient removal and conveyance of surface water or liquid. In some cases they are also used for attenuation or containment of same.

Channel drain, Line drain, Slot drain and ACO drain are terms often used interchangeably to refer to drains of a linear nature. However there is an important distinction to be made between some of them.

Channel drain

This is the generic term for linear systems that incorporate a channel together with an inlet detail that is embedded in the constructed surface.

The channel is longer than it is wide with a cross sectional dimension design to contain the flow from the associated surface surrounding the installation. The channel body can be manufactured from Polymer Concrete, Plastic or Steel.

The embedded inlet detail can vary considerably from cast iron, steel or polymer composite gratings through to an inlet detail or ‘slot’ that can barely be seen. Typically these inlets either sit or are formed as part of a channel body that sits below the surface.

Channel drains are typically structural formers that are integral to the performance of the system but may or may not be load bearing without the required surround detail.

ACO channel systems are used for external and internal applications, from Airports to Kitchens.

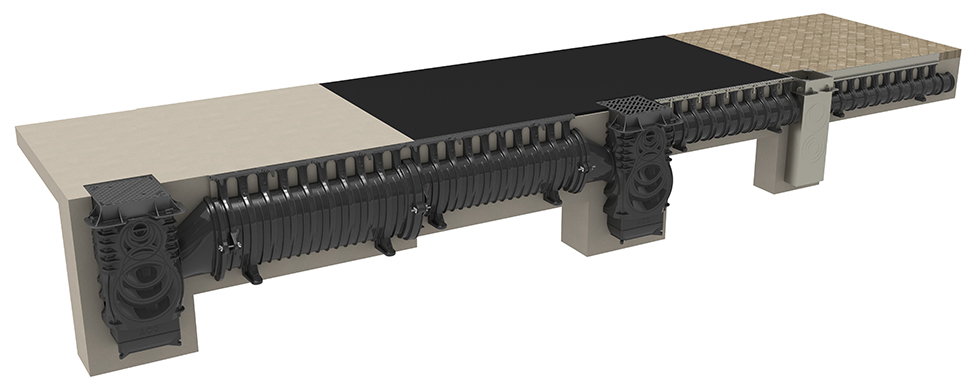

Slot drainage

This is a term that is often incorrectly used referring the broad family of ‘Channel’ systems. While it is a ‘channel system’ with a surface element and an underlying channel component, it differs in that the surface interface is defined by a discrete slot as opposed to a grating. This can be utilised by designers for aesthetic benefit without the need to compromise on the drainage capacity. It is also used in areas subject to heavy loading where it is important to eliminate moveable parts (Qmax is an example of this). As with channel systems the materials can vary from polymer concrete to plastic and steel.

More advanced forms of slot systems like the ACO Qmax although not load bearing in their own right, are formers that facilitate the construction of a ‘non-interrupted’ pavement.

Line (or, Linear) drain

This is the same as ‘channel’ drainage and often used interchangeably.The term is typically used to emphasise the difference over the more traditional ’point drains’. This is significant as linear systems tend to offer economic benefits over point drainage as a result of reduced underground piping and easier construction that results from the elimination of complicated falls or levels.

Because channels tends to be less deep than other systems it is particularly well suited when constructing drainage in areas with complex underground services and utilities. For this reason the term linear is used to emphasise the surface nature of channel drainage

Trench drain

This is a description that is less common in Europe and refers to all linear drainage systems above but also includes ‘cast in place’ solutions where the channel is formed in concrete poured into a trench made with wooden formers and rebar and then manually formed or in some cases mechanically extruded. These methods tend to suit applications that do not require anything other than a consistent linear form and restricted surface access.

Channel drainage is a key point in the management of surface water intercepting and conveying water to the next phase of it’s journey – a journey that has to be carefully and properly managed through cleaning, infiltration, attenuation and release. All ACO’s channel systems are design to integrate with other systems that address these particular elements of water management.

Our Design Team

Collaboration is very much a part of ACO’s way of working. For over 50 years we have been offering creative design solutions to all sectors of government, public and private enterprise and have a track record for development and regeneration informed by community aspirations and environmental context. Our in house design team and our external design engineers have excellent technical understanding of interconnected systems that can help you create sustainable drainage solutions in all categories of the urban environment.

Tools to support you

We also offer software for design surface to assist you in making your own calculations, as well as design visualisers to assist in helping assess impact of various grating/inlet details. BIM product files along with a variety of other support documents are all available for download here.

SLOT + CHANNEL DRAINAGE

SLOT DRAINAGE

CIVILS + INFRASTRUCTURE SLOT

Load Class D 400

Load Class D 400

BUILDING + LANDSCAPE SLOT

Load Class A 15

CHANNEL DRAINAGE

CIVILS + INFRASTRUCTURE CHANNEL

Load Class E 600

Load Class E 600

Load Class D 400

Load Class F 900

Load Class N/A

Load Class D 400

Load Class D 400

Load Class D 400

Load Class D 400

Load Class D 400

Load Class D 400

.png)

Load Class F 900

Load Class F 900

BUILDING + LANDSCAPE CHANNEL

Load Class A 15

Load Class A 15

Load Class B 125

Suggested Products

Multidrain

Load Class D 400