ACO: We put Hygiene First

Food production drainage that delivers hygienic performance.

As one of the world's leading commercial drainage specialists, ACO understands the critical role that drainage plays in a successful commercial food production business. We appreciate that food safety, hygiene and cost control are all vital factors yet we also understand that for many, drainage is out of sight and therefore out of mind.

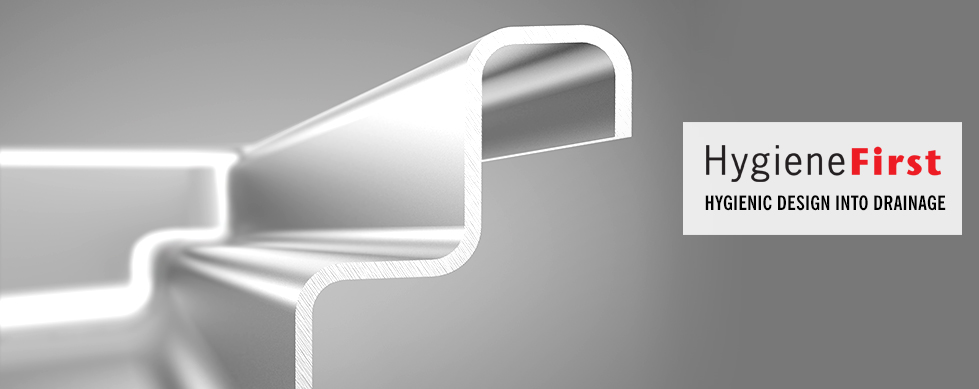

Our Hygiene First Channels

Through extensive research and development, we have become the first company to incorporate the latest hygienic design principles normally used for food production machinery into commercial drainage.

Our Hygiene First drainage channels when compared to normal channels provide increased cleanability and prevents bacteria build up.

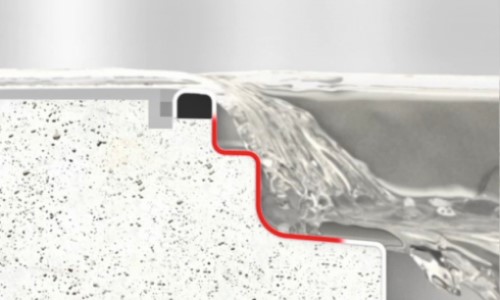

The internal 3mm radii allows easy and effective cleaning and all our Hygiene First Gullies are manufactured with a deep drawn process, thus creating an excellent hygienic solution for F&B and pharmaceutical sectors.

- The 14mm channel edge profile together with our edge infill provides increased durable and stable transmission from traffic over the channel to prevent cracking and the chance of bacteria growth.

To learn more about our Hygiene First channels watch the video below. To read more about how we've helped organisations throughout the food sector, click the case studies on the right of this page.

Products designed with hygiene in mind

ACO offers sustainable and integrated drainage systems designed to protect your business and environment. Our aim is to constantly improve every aspect of operational safety, hygiene and functional performance to meet the applicable standards for food processing application.

We are committed to deliver unparalleled benefits to anyone involved in the project specification, installation and subsequent operation of food processing and production applications. ACO HygieneFirst drainage systems fulfil the stringent hygienic requirements to minimise harmful bacteria and pathogen contamination of food arising from drainage elements by applying relevant hygiene design principles reserved for food contract surfaces by the implementation of BS EN 1672, BS EN ISO 14159 and EHEDG Document 8 requirements to drainage element design.

Featured Downloads

Login or register to download

Hygienic Drainage for Food Processing & Commercial Kitchen Applications

Download

Learn how we can help you assess your current and upcoming projects to ensure you get the optimal drainage system for your needs.

Download

Commercial Kitchens

All commercial kitchens can be characterised as a hazardous working environment - they are extremely busy with the potential for wet and greasy floors due to the abundance of fluids in both cooking and cleaning - and they are hot!

Food & Drink Manufacturing

Food touches every single individual on the planet in various aspects: health, pleasure, socialization, etc. More broadly food safety and access to food are fundamental prerequisites for public health, social stability but are also paramount for business sustainability and profitability.

Food Factories

All Areas

Kitchen / Tray channels

Load Class N/A

Load Class L15 / M125

Load Class N/A

Stainless Steel Gullies

Load Class A-C

Total Flow Gullies

Load Class A–B

Modular 125

Load Class A-C

SS Kerb

Load Class A 15

Access Covers

Load Class AA-D

Load Class AA-D

Load Class A–D

Load Class AA-B

Grease Management Systems

Load Class N/A

Engineered Solutions

Load Class A-C

Load Class A–B

Load Class A–B

Load Class A-C

Load Class A-C

Load Class A 15

Load Class A-C

Load Class A-C

Load Class A-C

Load Class A–B

Load Class A–D

Load Class A–B