ACO Grease Management Systems

Guiding you to the right grease management system for your kitchen

Commercial Kitchens are challenging working environments and regardless of whether you operate a sizeable commercial kitchen or are the owner manager of a small catering establishment, FOG can have major impact on your business. ACO’s high performance grease traps and grease separators are essential commercial kitchen equipment. They are specifically designed to help prevent the build-up of FOG in kitchen drainage floor gullies and ultimately avoid a fatberg in the main sewer network. To help guide you towards the right grease management system, we’ve created a series of guides along with an ACO product selector tool

Featured Downloads

Login or register to download

Learn more about the key design elements for effective drainage and grease management in your commercial kitchen to optimise hygienic performance.

Download

Download this guide to understand the legislation on grease and the pitfalls of not installing a grease separator in a commercial kitchen.

Download

Learn more about the importance of Grease management systems being used in commercial kitchens when they are being designed and built and the pitfalls of not including them.

Download

The grease management equipment options available to help prevent the build-up of FOG in commercial kitchens.

Download

To get an idea of the grease solution you would need for your establishment, add your details into the selector below:

Select the Kitchen

Select the MPD

Assumed Day Operating Time

Estimated NS Result

NS 5.5

Select our grease management solutions

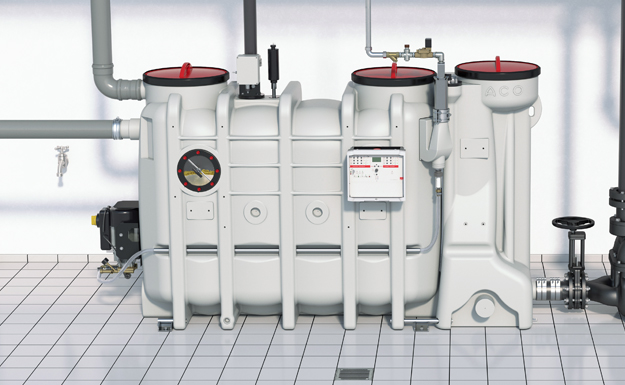

ACO LipuSmart

ACO LipuSmart products integrate the functions of grease separation, sampling, drainage using a lifting plant and a control system for the general system into one product.

Pressure sensors monitor the level of the separator and lifting plant. The plant control unit analyses both sensors and shows the filling level with centimetre precision in the display. If necessary, pumps are switched on and off or the flood alarm is triggered.

The flow of the LipuSmart pump equipment has been optimised by ACO in collaboration with the Institute for Process Machines and Plant Equipment (IPAT) to ensure optimum pump efficiency.

Can we help?

We have an in-house Grease Managment Team who are ready to assist you. Contact us for an obligation free consultation.

Call: 01462 810421

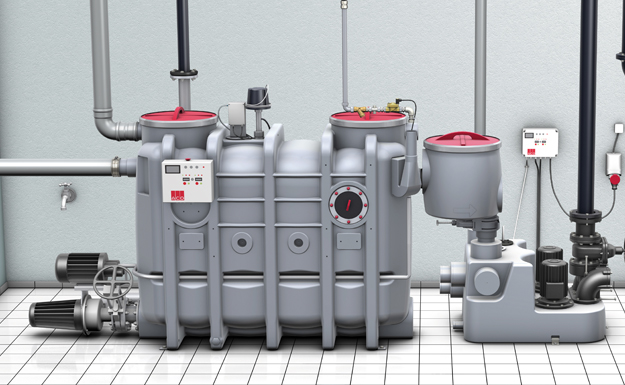

ACO LipuJet

ACO LipuJet separators are designed for applications where a free-standing grease separator unit is required.

Available in a wide range of sizes and specifications, LipuJet grease separators are easy to transport and assemble.

LipuJet products come with integrated sludge traps and are manufactured in either stainless steel or polypropylene to suit different customer requirements.

Can we help?

We have an in-house Grease Managment Team who are ready to assist you. Contact us for an obligation free consultation.

Call: 01462 810421

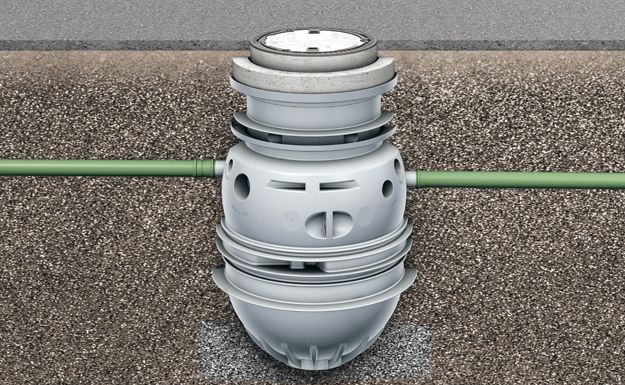

ACO LipuMax

The ACO LipuMax range of below ground grease separators are designed to efficiently separate fats, oils and grease from waste water.

Using advanced design, materials and manufacturing techniques, roto-moulding technology gives the below-ground tanks the structural integrity to withstand the rigours of site handling and installation as well as hydrostatic forces generated by changing ground water levels.

Delivering optimum durability and with a service life of 50 years, ACO LipuMax grease separators are manufactured, tested and certified in accordance with BS EN 1825.

Can we help?

We have an in-house Grease Managment Team who are ready to assist you. Contact us for an obligation free consultation.

Call: 01462 810421

Different types and sizes of commercial kitchen require different grease management solutions. Your choice of grease management solution will depend on a variety of key specification criteria including the size of your kitchen, the type of food you prepare, the equipment used for food preparation, the contents of your waste water and the density of the FOG produced.

Installing a serviced grease trap or separator can help:

- Keep your business running smoothly and avoid losing income due to kitchen closure while the drains are blocked.

- By preventing internal drain blockages and so avoid the cost and management time in organising jet washing of internal drains is greatly reduced.

- Avoid odours from your restaurant due to blocked drains that might lead to visits from Environmental Health Services.

For project-specific advice, please talk to our in-house technical design team who will help to ensure you choose the right grease management solution for your business and can advise on grease trap servicing to help you optimise product performance.

Grease management FAQ's

What is FOG?

FOG is the abbreviation for the fats, oils and grease which are found in the wastewater produced by kitchens. FOG comprises fats, oil, grease created by food debris, fats and oils used in the cooking process, and the washing of food equipment, utensils and crockery. All kitchens produce wastewater which contains fats, oils and greases (FOG) as well as food debris.

Why do I need to worry about FOG?

FOG causes blockages in kitchen drainage systems, compromises hygiene, creates unpleasant odours, can impact upon employee health and safety, and ultimately can stop your commercial kitchen from operating.

FOG is also becoming a major issue for Britain’s sewer network, creating ‘fatbergs’ and causing blockages. As a result, every foodservice outlet in the country has a legal obligation to “manage effluent content” under the Water Industry Act (1991). Section 111 of The Water Industry Act (1991) gives water companies the power to bring a criminal proceeding against anyone who causes injury or inhibits the free flow of the sewer network. As FOG is a major cause of sewer blockages, under this Act the water companies have the power to prosecute for FOG contamination and also to recharge any costs incurred to clear blockages.

What is Grease Management?

Grease management refers to the use of a range of products and systems which effectively remove FOG from waste water and so prevent the issues which FOG can cause in a kitchen’s drainage system and the wider sewer network.

What grease management solutions are available to prevent FOG from entering my drainage?

A range of solutions are available including grease separators, grease traps and grease recovery units also known as GRUs. It is important to specify the right grease management solution for your business and, to ensure it continues to operate effectively, to conduct ongoing maintenance.

Why are there so many different products and solutions to choose from?

Different types and size of commercial kitchen require different grease management solutions. Your choice of grease management solution will depend on a variety of key specification criteria including the size of your kitchen, the type of food you prepare, the equipment used for food preparation, the contents of your waste water, the density of the FOG produced and the space you have available for the installation of a grease management solution.

How can I ensure that I specify the most appropriate grease management solution for my business?

There are numerous sources of impartial information which will provide you with guidance. ACO has also developed a Product Selector for commercial kitchen operators.

When you are ready to specify the product, please the following questions before contacting ACO:

1. Is the grease trap to be internal, above ground or external below ground?

2. The number of meals per day that the kitchen will process?

3. Operating time of the kitchen in which the separators will be receiving grey water?

4. Type of food being processed Category A-E

5. The distance of the grease trap from the source?

If you opt to use an external below ground separator, please supply the following information:

1. Inlet from finished floor level?

2. Whether it is to be installed in a pedestrian or vehicular area?

3. Load class required for the access cover

Important points for consideration before installing grease management solutions:

· Ensure that there is suitable access for regular emptying, cleaning and maintenance

· Must be kitchen waste only, toilets must be plumbed in after the separator

· The separator cannot be used for dairy products

· If dishwashers are to be plumbed in, we will need to know the discharge volume and temperature.

For project-specific guidance, you can also talk with our in-house technical team who help you choose the right grease management solution for your business.

What are the cost implications of fitting a grease trap?

The initial capital cost of the grease management system that you choose will vary enormously depending on what you purchase. It is important to recognise that there will be regular maintenance and service requirements to ensure that the system remains problem free and provides the performance that you expect. It is worth reviewing this aspect before a purchase is made to understand the ongoing costs and requirements.

Will local authorities/ water companies provide grants to fit one?

It is unlikely that you will get any financial assistance from either your local authority or the local water company responsible for your sewer. We would suggest that you ask your local water company, local Environmental Health Officer or British Water (www.britishwater.co.uk) for guidance.

Why choose ACO?

ACO Building Drainage is the established leader in the provision of hygienic floor drainage systems and provides grease management systems designed and manufactured to support the functionality of commercial kitchens both large and small. We have more than 60 years’ experience of designing and manufacturing high performance drainage solutions, and our in-house design team provides tailored solutions to suit individual client requirements. To give you optimum peace of mind and a complete grease management solution, we can also put you in touch with our service and installation partner, who can manage your commissioning, installation and maintenance requirements.

Can I promote the fact that my restaurant is “doing its bit” to prevent fatbergs?

Promoting that your establishment is a ‘grease and fat-free establishment’ thanks to your partnership with ACO can only be positive. Given the recent interest in the London ‘Fatberg’ and the heightened awareness that consumers have regarding the challenges facing our cities infrastructure, it would be a tremendous message to communicate to your customers and staff. Social media is a powerful communication tool and positive messaging can support your business and brand.

Design, Commissioning, Installation & Maintenance

In addition to our range of solutions, we have the level of in-house technical expertise required to provide customers with guidance and support at every stage of a project from system specification to design. We can provide support through our preferred installation and service partners who will be able to handle system installation and commissioning and, if required, undertake the ongoing servicing and maintenance of your grease management solution.

Our ability to provide commercial kitchen operators with a complete grease management solution, means the design, installation and maintenance of the system is an easy, stress-free process which has the minimum impact on the business in terms of downtime and sales revenue

The decision to manage your grease

Ask the team

Whether your drainage system is being blocked on a frequent basis by fats, oils and grease, you’re looking to minimise downtime and cleaning time in your kitchen or you are committed to playing your part in the creation of healthy living and working

environments in our cities, the decision to manage the FOG output of your business will have a positive impact on you and the wider community.

Our expertise

No obligation guidance and support

Your choice of grease management solution will depend upon the nature and size of your kitchen, the contents of your waste water and the density of the FOG which your system needs to manage. Talk to our in-house technical design team about your specific project requirements and obtain expert guidance and advice about the best grease management solution for your business.

Installation and service

Service partnership

To give you optimum peace of mind and a complete grease management solution, we can put you in touch with our service and installation partners, who can manage your installation, commissioning, maintenance and regular service requirements.

We are proud to partner with market leaders in both the UK and Ireland.

UK: Aqua Mundus, http://www.aquamundus.co.uk

Ireland: John Hurt Environmental, http://www.johnhurtenvironmental.com

ACO Grease Traps

ACO Grease Traps are designed specifically for below-sink use in commercial kitchens and other foodservice establishments where space is limited and a larger grease separator cannot be installed.

ACO LipuMobil-P Grease Separator

The ACO LipuMobil-P grease separator is a flexible grease separation system which comes with a range of specification options. LipuMobil-P NS 0.8 has a total capacity of 48-litres and is certified to EN1825 for free-standing applications in frost-free areas.

ACO Grease Capture

ACO Grease Capture removes fat, oil and grease from waste water before it enters the drainage system and protects against blockages and the build up of Fatbergs.

ACO LipuMax

The ACO LipuMax range of below ground grease separators are designed to efficiently separate fats, oils and grease from waste water. Using advanced design, materials and manufacturing techniques, roto-moulding technology gives the below-ground tanks the structural integrity to withstand the rigours of site handling and installation as well as hydrostatic forces generated by changing ground water levels.

ACO LipuSmart

ACO LipuSmart products integrate the functions of grease separation, sampling, drainage using a lifting plant and system control into one product.

ACO LipuJet

ACO LipuJet separators are designed for applications where a free-standing grease separator unit is required. Available in a wide range of sizes and specifications, LipuJet grease separators are easy to transport and assemble. LipuJet products come with integrated sludge traps and are manufactured in either stainless steel or polypropylene to suit different customer requirements.

ACO Lifting station

A range of stainless steel and polypropylene lifting stations for use when the grease separator is installed below the backflow level.

Featured Downloads

Login or register to download

Technical brochure for ACO Above Ground Grease Separators EN1825

Download

An overview of ACO's Grease Management Solutions for Commercial Kitchens

Download

Technical brochure for ACO Below Ground Grease Separators EN1825

Download

ACO's Commercial Kitchen & Food Processing Drainage Systems brochure

Download

ACO clears the FOG for Zizzi restaurant at Kings College, Cambridge.

DownloadGrease Management Solutions

Grease Management Solutions

Grease Management Solutions

Load Class N/A

Load Class N/A

Load Class N/A

Load Class N/A

Load Class N/A